News

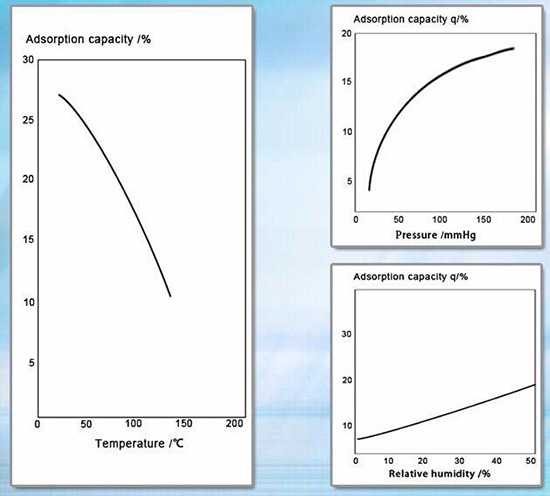

3A molecular sieve water adsorption curve

3A molecular sieve water adsorption curve

prolong the service life of molecular sieve. It is the preferred desiccant necessary for gas-liquid phase deep drying, refining and polymerization in the petroleum and chemical industries.

concrete application:

Drying of various liquids (such as ethanol), drying of air, drying of refrigerants, drying of natural gas and methane gas, drying of unsaturated hydrocarbons and cracked gas, ethylene, acetylene, propylene, and butadiene.

Precautions:

The molecular sieve should be prevented from pre-adsorption of water, organic gas or liquid before use, otherwise, it should be regenerated.

Regeneration of molecular sieve:

Removal of water: depending on the pressure, temperature and water content of the regeneration gas. Under normal circumstances, the dry gas at 200-350°C will pass through the molecular sieve bed for 3 to 4 hours at a pressure of 0.3-0.5Kg/cm² to bring the outlet temperature to 110-180°C and cool.

Removal of organic matter: replace organic matter with water vapor, and then remove water.

Molecular sieve storage: room temperature, relative humidity not greater than 90% indoor: avoid water, acid, alkali, isolation of air, airtight storage

3A adsorption curve

1. It can be seen from the figure that our 3A molecular sieve has the best water adsorption capacity under normal temperature conditions. As the temperature rises, the adsorption capacity gradually decreases, and almost no longer adsorbs after 100 degrees. . Above 150 degrees, the molecular sieve begins to regenerate.

2. The adsorption of 3A molecular sieve is related to pressure. As the pressure increases, the amount of adsorbed water also increases

3. The adsorption of 3A molecular sieve is also related to the surrounding environment. The higher the humidity of the surrounding environment, the higher the adsorption capacity until saturation.

Zeolite Products

Latest News

Contact Us

Contact: Ms.Anna Fei

Phone: +86-15036079565

Tel: +86-371-64368520

Email: info@meiqicn.com

Add:BEISHANKOU TOWN, GONGYI CITY, HENAN, CHINA 451200