News

The construction of zeolite molecular sieve system and its application in ultra-deep hydrogenation desulfurization.

According to the BP world energy statistics yearbook (2017) released by BP on July 5, 2017, oil currently accounts for 1/3 of the world's total energy consumption, and is the largest energy consumption of all kinds.

Our country is the second largest oil consumer after the United States, but with global oil rising trend of heavy, quality as well as the increasing of our country's foreign oil dependency, secondary processing high sulfur content in gasoline and diesel products is also more and more.

As of January 1, 2017, China has fully implemented the standard of V gasoline diesel, requiring that the sulfur content in the vehicle fuel should not exceed 10 PPM.

So, how to achieve the production of sulfur content from the low quality raw materials to meet the requirements of the current national standards?

Recently, China university of petroleum (Beijing) ya-song zhou team developed directly by the conventional inorganic silicon aluminium salt synthesis skeleton of Ga - micro hole composite Y type zeolite molecular sieve, the preparation of a kind of high performance of hydrogenation desulfurization catalyst materials.

The combustion of sulfur compounds in vehicle fuel has adverse effects on the atmosphere and human health.

In recent years, the world's leading automotive fuel consuming countries have introduced sulfur content is not higher than 10 PPM of clean vehicle fuel standards, which requires the refiner complete removal of all types of sulfur compounds in petroleum fractions, especially high unsaturation larger, more complex structure, space steric hindrance of 4, 6 - dimethyl 2 benzothiophene (4, 6 - DMDBT) type of sulfur-containing compounds.

And now with alumina as the carrier of industrial catalyst for this class of sulfur-containing compounds removal activity is not high, with zeolite molecular sieve as the carrier of catalyst are showed more significant effect of mass transfer limitation.

Therefore, the preparation and application of microporous zeolite molecular sieve with high efficiency and controllability have attracted wide attention of scholars both at home and abroad.

However, it is worth noting that the process of direct preparation of zeolite in zeolite between 1-10 is not reported.

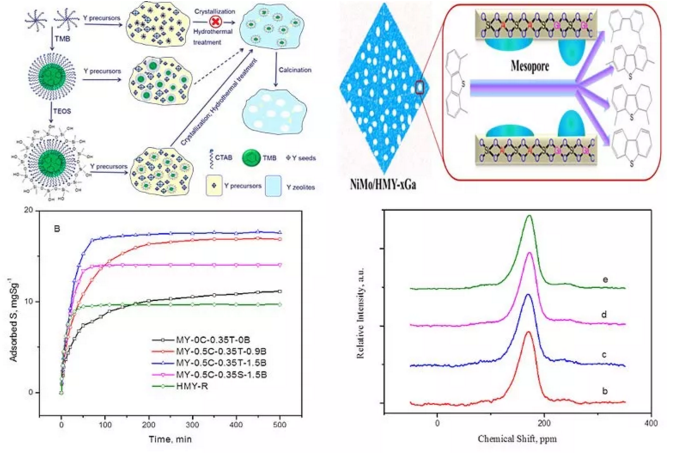

Based on the above technical problems and the demand of the practical application, professor ya-song zhou fine team designed the SiO2 @ CTAB mesoscopic micelle, by adding three toluene (TMB) as a swelling agent to adjust the mesoscopic, alcohols compound micelle size adjust the Zeta potential of mesoscopic micelle, starting from the conventional sources of inorganic Si, Al, three steps by hydrothermal synthesis method directly synthesized with narrow distribution of mesoporous properties interface - micro hole Y type zeolite molecular sieve composite materials.

On this basis, the research team by adding inorganic salt as a source of Ga Ga synthesis system synthesized skeleton Ga/Al ratio is different - micro hole Y type zeolite molecular sieve composite materials, and the preparation of zeolite molecular sieves materials as catalyst substrate material to build the function of double, double metal NiMo/MY - xGa series catalyst.In this work, the mass transfer resistance of zeolite zeolite in the diffusion process of 4, 6-dmdbt was significantly reduced, and the equilibrium adsorption of 4, 6-dmdbt was higher.

The synthetic skeleton contains Ga - microcomposite pore Y zeolite molecular sieve. All Ga species are in the zeolite skeleton.

It is worth noting that the work shows that adding Ga species to zeolite skeleton can significantly regulate the active phase structure of the corresponding hydrogenated desulfurization catalyst.

The catalytic activity of the catalyst for the hydrodesulfurization of 4, 6-dmdbt was very high.

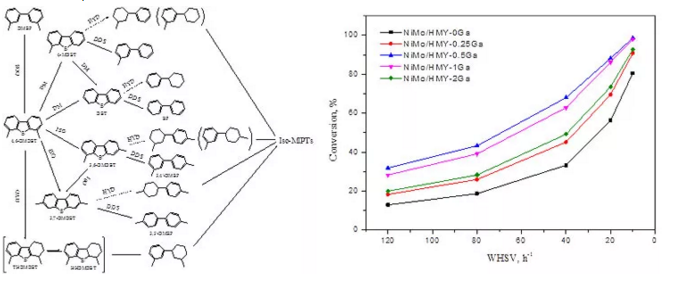

The team the root cause of the catalytic activity was studied to improve further system, through dynamics research found that in the corresponding catalyst in hydrogenation of 4, 6 - DMDBT path is obviously different from the traditional catalyst in 4, 6 - DMDBT hydrogenation transformation path: in addition to the traditional path of HYD and DDS, corresponding catalyst in 4, 6 - DMDBT can be generated through ISO path 3, 6 - DMDBT and 3, 7 - DMDBT, thus make S atomic fully exposed, and significantly reduce the space steric hindrance of reactant molecules;

In addition, 4, 6-dmdbt can also have direct demethylation in the corresponding catalyst (inverse Fourier alkylation reaction), and 4-MDBT and DBT with simpler structure and less space resistance.

The results showed that the selectivity of the ISO + DDM pathway in the catalyst was as high as 92% and 88% when the molecular sieve framework Ga/Al ratio was 0.5 and 1, thus showing the highest catalytic activity.

The above research is of great theoretical significance to realize the production of gasoline and diesel distillate in accordance with national automobile fuel oil standard under the condition of low hydrogen consumption.

The relevant results were recently published in the Chemical Engineering Journal [1] and ACS Catalysis [2], and the first author was Dr. Zhou wenwu, professor zhou yatong of China university of petroleum (Beijing).

The work was done under the auspices of the national natural science foundation's joint fund for petrochemicals.

Zeolite Products

Latest News

Contact Us

Contact: Ms.Anna Fei

Phone: +86-15036079565

Tel: +86-371-64368520

Email: info@meiqicn.com

Add:BEISHANKOU TOWN, GONGYI CITY, HENAN, CHINA 451200